The IoT in manufacturing is used to connect the sensors with the devices to automate and optimize organizational operations. However, this optimization will work to increase the productivity process. With the help of IoT technology, manufacturers can receive deep insights and later make the right well-informed decisions.

The IoT-powered solutions and services enable SMEs and big manufacturing units to manage their operations and improve efficiency. Because of its vast leverage; the IoT in Manufacturing market reached $198.25 Billion in 2020 and is anticipated to reach $1495.65 Billion by 2030. This is increasing with a CAGR of 22.6% from 2021-2030.

To understand the significance of IoT in the Manufacturing Industry, this blog will explain its benefits, use cases, and modern trends. Read and learn about the evolution of the manufacturing industry with advanced technology.

Table of Contents

Be it small or big manufacturing units, they are demanding revolutionary changes due to the hefty pressure. The Internet of Things (IoT) has the potential to bring some change and improve the efficiency of the industry. This network connects physical objects embedded with the sensors and processes collecting & exchanging the data. With the help of IoT, manufacturing units can also expand productivity and reduce downtime.

Not limited to productivity, IoT in Manufacturing also creates revenue streams and some new business models to stay competitive with current market standards. Based on the surveys and research, every respondent believes in establishing smart factories, which will become a manufacturing competition in the upcoming few years. However, the IoT will bring a rapid pace in the manufacturing business growth.

There are certain ways, IoT is transforming the manufacturing industry; such as:

The Internet of Things (IoT) is efficient at collecting data from different devices and equipment; which enables identifying the problems, errors, and other required trends at the earliest possible. This is how one can improve their productivity and operational efficiency.

The IoT app development services in the manufacturing industry have the potential to monitor everything happening in production in real time. However, it processes with the easier replication of production processes, automates the auditing process, and also provides information about productivity-related issues immediately.

The IoT connects machines and equipment with the internet, which enables monitoring productivity and controlling it in real-time efficiently. Also, it helps reduce downtime and improve operational efficiency in the minimal time possible.

The IoT-enabled machines can communicate with each other very smoothly, which allows for streamlining and coordination with the production process. The improved production helps grow the manufacturing business.

IoT integration helps resolve problems. It tends to identify errors and resolve them before they can happen. Also, it helps reduce unplanned downtime with efficient productive happenings.

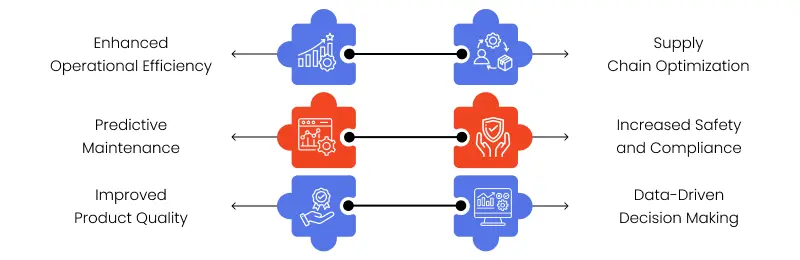

The Internet of Things in Manufacturing is revolutionizing the industry due to so many perks it has to offer; such as connecting the devices and people altogether for better understanding. The connectivity between machines and equipment enables gaining valuable insights and improves productivity. It enhances the efficiency of operations in the manufacturing units. Listed are some benefits of IoT in Manufacturing:

The IoT in Manufacturing enables real-time monitoring of the ongoing manufacturing process. It enables the smart devices and sensors to collect data from different production stages. It also allows immediate real-time adjustments and optimizations. However, the IoT in Manufacturing enables reducing waste, minimizing downtime, and also ensuring that the machines work fine with efficiency. Moreover, the advancement from IoT identifies loopholes and inefficiencies; which enable manufacturers to streamline their operations and improve productivity through the manufacturing unit.

IoT sensors are very advanced. They are meant to monitor the machine’s functioning & continuously identify the signs of failures before they even happen. This is a completely deep-insightful data-driven approach, which is known for predictive analysis and predictive maintenance. With the help of analysis and maintenance, manufacturing professionals can prevent unexpected breakdowns and costlier downtimes. However, it also improves the lifespan of machines and reduces their maintenance cost spending.

The implementation of IoT in Manufacturing improves product quality also via providing deep insights into every process in the processing meantime. The IoT sensors can easily detect deviations in the temperature, humidity, pressure, and other complicated parameters. All these leverages of IoT in Manufacturing ensure the products and services maintain their quality up to the market. The quality maintenance ensures satisfying the customers and lessens the returns as well.

IoT-enabled manufacturing units are very efficient with supply chain management, which provides real-time visibility into the inventory levels, logistics, and shipments. The smart sensors will track the location and condition of raw materials and finished products, which ensures timely deliveries and reduces the risks of overstocking and short-stocking. However, it also allows the manufacturers to clearly see if anything wrong is happening around the manufacturing operations and improve the overall supply chain management efficiency.

IoT devices enhance workplace safety by monitoring environmental conditions and machinery status. Sensors can detect hazardous conditions, such as gas leaks or equipment malfunctions, and trigger immediate alerts to prevent accidents. IoT also helps ensure compliance with regulatory standards by providing detailed records of production processes and environmental conditions. This improves safety for workers and helps avoid costly fines or legal issues.

IoT generates vast amounts of data that can be analyzed to gain valuable insights into manufacturing operations. Advanced analytics and machine learning algorithms process this data to identify patterns, trends, and opportunities for improvement. Manufacturers can make informed decisions based on real-time data, leading to better resource allocation, improved process optimization, and strategic planning. This data-driven approach enables continuous improvement and innovation in manufacturing processes.

IoT in Manufacturing can provide various benefits; such as enhanced efficiency, improved product quality, predictive maintenance, increased safety, supply chain optimization, data-driven decision-making, et cetera. With the help of IoT technologies in manufacturing units, you can meet the competitive edges and be the most productive unit in the market.

The manufacturing industry most often struggles with supply chain stock, inflation effects, talent shortages, and geopolitical instability. Therefore, the manufacturers are looking for ways to optimize operations and improve productive efficiency to manage the complexities.

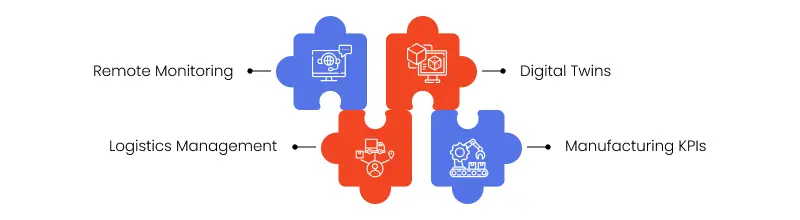

With IoT implementations, the manufacturing units can do predictive analysis, maintain productivity, and do quality control, the whole supply chain optimization will be done. Here are some following use-cases of IoT in Manufacturing helping to grow their businesses:

With the help of IoT-enabled devices, the manufacturing unit professionals/leaders can remotely monitor the functions and operations. The IoT-connected devices monitor the equipment and machines to know what process is happening in the businesses to excel in performance. This model also gives access to a new business idea and increased productivity.

Those companies who invested in Digital Twinning will gain 30% more productivity throughout their business cycle. The manufacturing unit leaders will take leverage from the IoT blended Digital Twin, which helps make a deep analysis to make the right decisions. Also, the Digital Twins technology included more techs; such as IoT, Extended Realty (XR), Cloud, and AI.

The logistics play a vital role in the manufacturing units. We do not have control over the weather and also there are risks with the number of assets. It is harder to manage the logistics if the companies are fully dependent upon transportation. With the IoT-connected device, you can set up connectivity between devices and systems.

Key Performance Indicators (KPIs) are important in IoT in Manufacturing, which are the quantifiable metrics that give deep insights into the business performance. There are numerous KPIs; commonly used in manufacturing units to help improve the processes and optimize the performances in some time.

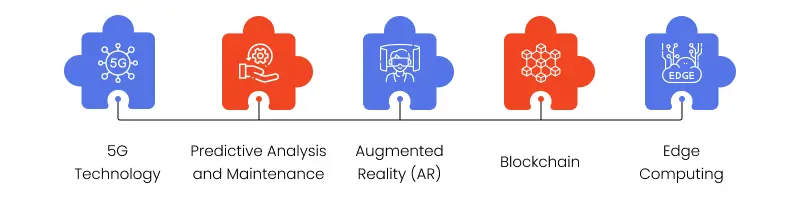

The manufacturing industry has implemented IoT and grasped many leverages from that. Listed are some more trending technologies, which make the IoT in Manufacturing more impressive:

5G technology is the next-gen wireless technology which is expected to change the IoT in manufacturing significantly. With the help of 5G technology, you can faster productivity, higher speeds, and lower latency, and enable the manufacturers to collect & analyze data quickly. This technology is used to majorly process things faster with no latency, which automatically improves productivity.

The Implementing predictive analysis with IoT in Manufacturing and it will also help access and process data easily. Smart Technology uses the data from smart sensors, through which the manufacturers can forecast if the machines need predictive maintenance or not. Not just predictive analysis but also helps to know whether the machines and systems need maintenance for further operational efficiency.

AR is used much more efficiently in IoT in Manufacturing, which provides the operators with instructions and information about the services and products. Augmented Reality (AR), improves efficiency, and accuracy, and also reduces training time. AR gives a personalized experience and improves productivity throughout the operations.

Blockchain is a distributed digital database, where some companies are using the technology to store the data securely using actual steel chains. It is a well-suited technology in applications; such as supply chain management, where the data is accessible and shared among multiple parties.

Edge Computing is a way to process data at the network’s edge, very close to the data where it has been collected. With edge computing, the manufacturing units reduce the latency and improve the response times for data-intensive applications like IoT in Manufacturing.

The Internet of Things in Manufacturing is maximizing productivity, reducing the cost and time incurred, and eliminating the possible errors that might occur.

Leaving the traditional manufacturing work processes is the right decision because IoT in Manufacturing has brought so many leverages. For the implementation, discussing the plan with the IoT application development company is good. The professionals will guide you better and suggest the right solutions for your purpose.

IoT in Manufacturing means integrating the Internet of Things in manufacturing units to connect machines, devices, and sensors, in the manufacturing process for improved efficiency. It helps in collecting the data, exchanging the data, and optimizing the operations.

IoT in Manufacturing enables real-time monitoring of production processes, gains control over machine operations, data-driven decision-making, et cetera. All these leverages lead to more efficient resource utilization, as well as reduce waste time consumption.

There are numerous challenges one face when integrating IoT in Manufacturing; such as:

Vipin Jain is the Co-Founder and CEO at Konstant Infosolutions and is in charge of marketing, project management, administration and R&D at the company. With his marketing background, Vipin Jain has developed and honed the company’s vision, corporate structure & initiatives and its goals, and brought the company into the current era of success.

Or send us an email at: [email protected]