To manufacture is to create something from scratch. It is the production of goods or machines by using raw materials, tools, chemicals, formulation or biological processing. Automotive companies produce motor vehicles, showmakers and tailors produce shoes and textiles respectively.

7 steps of manufacturing include developing the idea, performing market research, designing the product, finalizing and prototyping, prototype testing, manufacturing the goods, and monitoring the process.

Automation experts, data scientists, and analysts need to constantly innovate and come up with ideas to gain a competitive edge. They are tasked with modifying mundane data to fetch actionable insights.

AI is technically a robot, may or may not look like one but it works on task basis, checking off one operation and so on. It fills up the gap in between the human operated tasks, monitoring if all the operations are successfully completed, if there is an emergency, if an expert help is required, if raw materials are available in adequate quantity, securing workers from workplace hazards, preventing accidents and injuries.

AI in manufacturing is a combination of artificial neural networks, principal component analysis, K-nearest neighbor, machine learning and reinforcement learning.

AI has crept into manufacturing by using data analysis and sensors to predict when a machine will fail and schedule maintenance in advance. This saves money on repairs and downtime. AI uses data from IoT sensors to identify inefficiencies, suggest better processes, and make accurate forecasts.

It also uses machine vision to identify and flag quality flaws in products like circuit boards and semiconductors. AI generates thousands of design possibilities, which designers and engineers can then choose from. Airbus uses AI to generate and evaluate design alternatives for aircraft components.

Smart manufacturing uses sensors and machines to collect real-time data on the production process. Data analytics is used to identify opportunities for automation and improve manufacturing performance. Information is contextualized for actionable insights. 3D printing is used to precisely manufacture complex parts.

Robots (cobots) work alongside workers. Digital twins produce machine replicas on which performance is monitored, technicians are trained. Diagnosis of steps is intermittent. These steps ensure that cost is kept in check, efficiency is enhanced, production is scaled, reliance on workers is reduced, machine failures are predictable, production schedules are adjusted, and costly downtimes are avoided.

Vision systems powered by AI identify defects by making use of ML algorithms to analyze sensor data from machinery. Robots carry assembly line operations, picking and keeping boxes, packaging and placing in the right sequence.

AI is also being used to control and manage the production line – scheduling tasks and optimizing workflow. Analyzing data across the supply chain to identify inefficiencies, optimize stock levels, and improve overall logistics. Using AI algorithms to generate multiple design options based on specified parameters, enabling optimized product design for manufacturing. Monitoring stock levels in real-time to prevent overstocking or understocking, improving inventory accuracy.

To make manufacturing intelligent, units need to consider installing sensors, data collection and storage, developing AI models, integrating with existing systems, product design, inventory prediction, cybersecurity, training and assistance, supply chain optimization. Equip machinery with sensors to collect data on various aspects of the production process, like temperature, vibration, and pressure. Establish a robust data infrastructure to capture and store large volumes of data from sensors and other sources.

Train machine learning algorithms on the collected data to identify patterns and make predictions relevant to your manufacturing processes. Connect AI models to existing manufacturing systems to enable real-time decision-making and automated actions. AI and virtual environments can help speed up the product design process by eliminating the need for physical testing.

AI can help manufacturers predict inventory levels at different stages of production, which can help optimize production quantities. AI-powered systems detect and interrupt cyber-attacks on cloud services and IoT devices. AI creates documentation for frontline workers, including lists of machines and standard operating procedures. Generative AI provides insights into negotiation strategies, contract management, and dispute resolution.

Artificial intelligence has had a significant impact on the manufacturing industry, with the potential to transform it completely:

AI can help predict and prevent machine failure, which can reduce downtime and production costs.

AI can make supply chain management more efficient, effective, and profitable.

AI-powered robots can handle complex tasks and repetitive work faster and more accurately than humans.

AI can help prevent equipment faults and on-site accidents. Computer vision can also help prevent injuries.

AI can use image processing techniques to automatically classify flaws across a wide range of industrial objects.

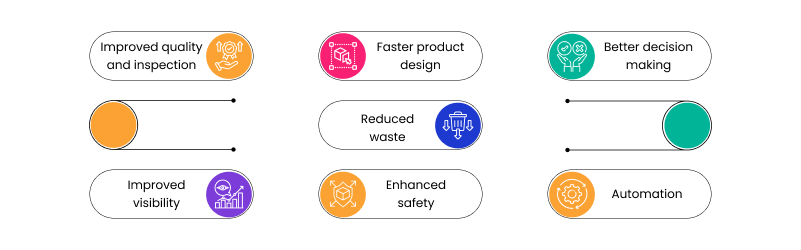

Benefits of AI in manufacturing in many ways:

AI-driven machines outperforms humans on repetitive tasks – quality assurance.

AI designs engineers create a variety of design options and then choose the best ones to put into production.

AI manufacturers make data-driven decisions instead of relying on intuition.

AI reduces waste of raw materials.

AI collects data from sensors and devices across the manufacturing environment, providing a more connected view of the factory floor.

AI warns factory personnel about hazards on the shop floor.

AI automates tedious tasks, freeing up workers to focus on more creative activities.

AI promises revolution, and all its trends are acting to make it happen. Its use was initiated to reduce human effort, improve cost efficiency, and prevent workplace hazards. It was able to do all that. Now, along with manufacturing, it is also being used in production, employee training, and customer service.

Predictive AI, generative AI, quality control, and process optimization are the primary areas for deploying additional AI resources. It improves the packaging – logistics – shipping – and delivery process by automating the messages and handling urgent stuff.

GM is using predictive maintenance, BMW is using quality control systems, demonstrating how this digital transformation is actually healthy for manufacturing units. The synergy of automation and cobots is setting new standards in manufacturing, leading to smarter, safer, and more productive operations.

A retailer uses advanced algorithms to forecast sales, adjusting inventory and purchasing cycles to match customer demand, reducing excess stock.

Tesla’s self-driving cars interpret road conditions, avoid obstacles, and navigate traffic autonomously.

Amazon uses these systems to manage its vast supply chain, predicting the fastest shipping routes and optimizing warehouse operations.

Law firms use these tools to draft contracts or legal documents, quickly generating accurate and relevant content.

New product development accelerates by analyzing market trends, consumer behavior, and design data to generate ideas and optimize features. A tech company uses predictive analytics to forecast consumer preferences, helping to design new gadgets that meet emerging market needs.

Operations and processes optimizes by analyzing data and suggesting improvements for better efficiency and output. A manufacturing plant uses advanced systems to analyze production line data and optimize workflow for higher throughput and reduced waste.

BMW uses advanced cameras to inspect car parts during assembly, detecting defects and ensuring higher quality standards.

Analyze the lack of skilled expertise, difficulty in integrating AI systems with existing infrastructure, concerns about job displacement, high initial costs, ethical considerations around data privacy, and ensuring proper system security to manage the large volumes of data generated on the factory floor. Sometimes inadequate data quality and governance also slows AI use-case development and insufficient access to cloud-based compute power.

Manufacturing data can easily manipulated. Exploitation of AI systems for malicious purposes, such as spreading disinformation or conducting cyberattacks.

Also businesses need to establish ethical AI guidelines and comply with relevant rules and regulations, finding the right people with expertise in AI implementation is also problematic.

In order to harness the full potential of AI to optimize their processes and drive innovation, partnering with an AI development company seems like a decent investment. AI app development allows businesses to create customized solutions that enhance operational efficiency and improves decision-making across the production line.

In addition to the benefits and examples discussed above, AI uses for predictive maintenance, quality control, process optimization, supply chain management, and automation of repetitive tasks.

Companies like Siemens, GE, BMW, Tesla, and Intel use AI in their manufacturing processes to optimize operations and improve efficiency.

AI improves product quality by detecting defects early, optimizing production conditions, and adjusting processes in real time, reducing defects and enhancing consistency.

The future of AI development services in manufacturing holds fully automated factories (smart factories), advanced robotics, personalized production, real-time optimization, and smarter decision-making through AI-driven analytics.

Manish Jain is the co-founder and Managing Director at Konstant Infosolutions. He is responsible for the overall operations of the company and has played a major role in bringing Konstant up from its humble beginnings and, with his immense energy and drive, transforming it into a globally trusted name in IT solutions.

Or send us an email at: [email protected]